New Machinery Review: Fendt electric e107 V Vario tractor

26th September 2023

Fendt will officially launch its battery-powered e107 v Vario tractor at the German Agritechnica show this November. Fruit & Vine machinery editor David Williams enjoyed an early test drive.

Series production of the e107 V Vario will commence in late 2024, and early deliveries will be to selected markets including Germany, Norway and the Netherlands with UK availability expected later. The e107 V Vario was first shown as a concept at Agritechnica in 2017, but an exclusive press event at a German vineyard this September was the first opportunity to see it in action.

Home-produced electricity

Fendt points out that many fruit farms and vineyards produce their own electricity through solar panels and these can provide virtually free ‘fuel’ for the tractor. Additional advantages highlighted from using battery-powered tractors include reduced maintenance costs, and the lack of local exhaust emissions and hot exhaust fumes, making them ideal for working in polytunnels and greenhouses.

Utilising proven technology

The e107 V Vario is based on the 200 Vario-series specialist narrow tractors. Where many electric vehicles have direct drive from the motor to the wheels, Fendt has chosen to replace the conventional diesel engine with an electric motor and drive the wheels through the standard Vario stepless transmission.

The lack of fumes and the blast from a hot exhaust are advantages when operating in poly-tunnels and greenhouses.

Use standard implements

Fendt product specialists explained that retaining the standard drive arrangement allows existing front- and rear-mounted PTO-driven attachments and implements to operate with the tractor without adaptation. The new e100 V Vario can be easily integrated into a mixed tractor fleet and fully utilised, and fleets can be updated one tractor at a time. The specialists also pointed out that no industry standards have so far been agreed in terms of electrical voltage or connectors, so retaining the accepted system makes sense.

The Vario transmission is extremely efficient with minimal power losses and allows infinite speed control in forward and reverse. It also contains the PTO activation clutches and hydraulic supply circuits.

The first model to receive the battery power treatment is the narrowest V vineyard version, and wider P and F Fruit variants as well as standard width models will be available later.

The e107 V Vario beside a conventional diesel 211 Vario at the event.

Power equivalent to popular diesel version

Power is from a 700-volt, 100kW capacity battery. The motor has three operating modes.

Eco 50kW provides power equivalent to a 70hp diesel engine. Dynamic mode produces up to 55kW (approximately 55hp) and Dynamic Plus produces 66kW (approximately 90hp), but this is available for limited periods and only while safe working temperatures are maintained.

Maximum torque produced by the motor is 347Nm, 20Nm more than the standard diesel-powered 207 Vario.

The cooling fan draws air from the rear to prioritise battery cooling.

Maximise working efficiency

As with other battery-powered vehicles, the working time available between charges varies depending on multiple factors, but Fendt quotes 4–7 hours of operation. Power recuperation systems maximise working times, and a floor-mounted pedal that usually operates an exhaust brake has been adapted to use the electric motor as a brake while generating electrical current which is fed back to the battery.

Tyres fitted to the test tractor have been specially designed to minimise rolling resistance and extend operating time between charging.

Operates like a standard diesel engine

The electric motor operates continuously, and its speed reduces to an idle when the tractor is stationary like a conventional diesel engine. When working, then the engine and transmission management system constantly adjusts the Vario transmission to achieve the most efficient motor speed for the application. When the tractor stops moving the motor runs at low speed until it is switched off or the parking brake is applied and neutral is selected.

The cab and lighting systems are 12-volt – like the standard 200 Vario-series tractors except for the climate control which is powered from the high-capacity main battery.

There are no electrical outputs apart from the standard 12-volt lighting socket, so the e107 V Vario cannot be used as a mobile power supply. This is mainly due to the lack of an industry standard.

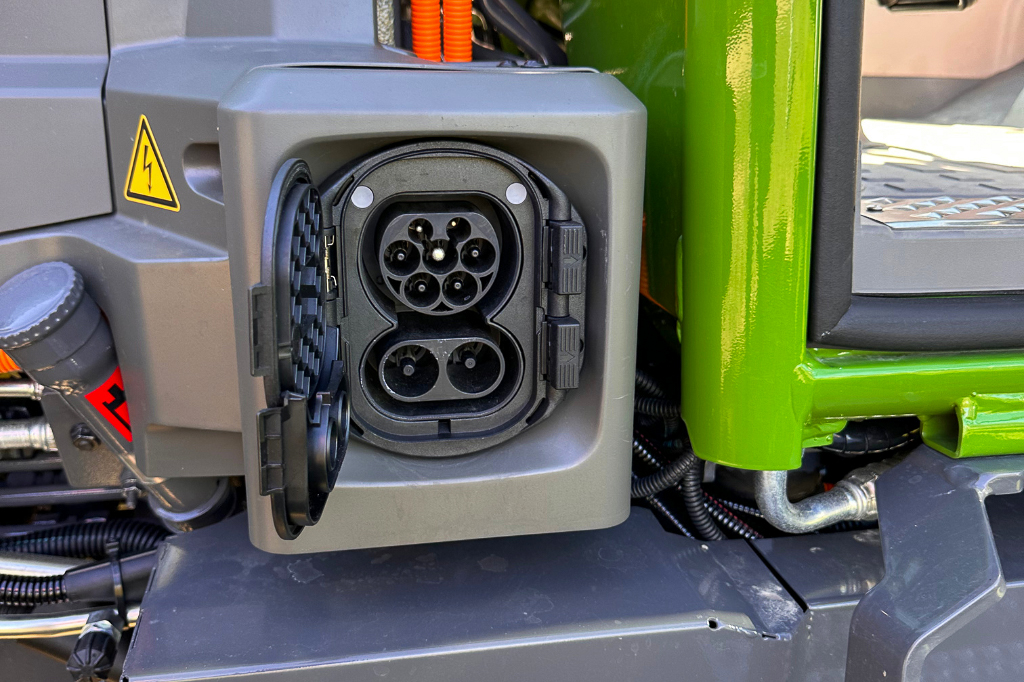

The charging socket is identical to the type used on cars.

Optimised charging

Charging is through a standard 22kW car-type socket. Rapid 80kW DC chargers can also be used, achieving a full charge from 20–80% capacity in only 45 minutes. If higher rate chargers are used, then the electric flow is automatically restricted to prevent battery damage. Battery life can also be optimised by restricting the charge rate. This is ideal when the tractor is left on charge overnight, for example, where there is no need for rapid charging. Also, when the maximum working time isn’t needed, then the tractor system can be set to stop charging when the battery capacity reaches a pre-set level, helping extend the service life.

The roof-level terminal displayed the electrical system status.

Added convenience

An advantage of battery power over conventional diesel-fuelled models is that operators can set a start time and the cab heating system will activate to achieve a pre-set temperature before work commences. This can also prepare the battery for work on cold days, as an operating temperature of 25–30 degrees centigrade is needed for maximum working efficiency. Using the pre-heating systems while the tractor is charging takes power from the mains supply rather than the battery, so maximum working time remains available.

The electric motor, battery and Vario transmission are all cooled by an electric-powered fan. Air is drawn from the rear to the front to prioritise battery cooling, and the fan direction can be reversed to alternate the air flow and keep the cooling packs and air intake grills clear of loose debris and dust.

The cab heating system is designed for maximum efficiency and to reduce demand on the battery. Fendt explained that heat applied direct to the operator is more efficient than circulating warm air around the cab so the seat and floor both contain heating elements. Heated front and rear windows are an option to keep them clear on cold or damp days.

The cab makes best use of the space available and offers great all-round visibility.

Purpose-designed tyres

The tyres have also been designed to maximise working times between charging. Made by Trelleborg, the TMI Ecopower tyres have a low rolling resistance, and their environmental credentials include manufacture using 60% recycled materials.

The e107 v Vario weighs approximately 150kg more than the standard 207 Vario.

The new Fendt tractor will be available to order from November for customers in the selected markets, with a price approximately 1.5 to 2 times as much as the equivalent diesel 207 Vario.

Fruit & Vine tried the new e107 V Vario pulling a fully loaded sprayer.

Test-drive

Fruit & Vine tried the new e107 V Vario pulling a fully loaded sprayer at high road speeds up to 40kph and on soft ground in the polytunnels.

The FendtONE operating concept is the same as standard diesel models, allowing operators to customise the terminal displays and controls to suit their preferences and the application. The test tractor had the standard 10in dashboard terminal displaying essential operating information, and the roof-level 12in terminal displayed the electrical system status including the battery charge state, as well as the amount of electrical energy being consumed by ancillary systems.

Operating the tractor is little different to the diesel version. Switching on the ignition, the displays come to life and the electric drive motor runs quietly. Forward or reverse is selected, and the parking brake is released, then depressing the accelerator pedal or pushing the main joystick forward starts the tractor moving.

Fruit & Vine tried a pre-production version of Fendt’s battery-powered specialist narrow tractor towing a full 1,000-litre Wanner sprayer.

There is no direct relationship between the position of the accelerator pedal and the speed of the motor as the Vario management system constantly adjusts the transmission ratio to achieve the lowest possible motor speed for the selected speed and task. There is plenty of power and acceleration when needed, and it is easy to maintain constant speeds even when climbing or descending slopes and travelling over undulating ground.

The PTO operates just like the standard tractor, including selecting the required motor speed to maintain the correct PTO revs. Travel speed is then adjusted using the foot pedal or joystick, and two pre-set speeds can be saved and recalled through the cruise control.

Cab noise levels are much lower than a diesel machine, there is a complete absence of vibration, and the ride quality and cab comfort are excellent.

The lack of fumes and the blast from a hot exhaust are advantages when operating in poly-tunnels and greenhouses.

The verdict

The battery-powered Fendt won’t suit every customer, and where long periods of field and transport operation away from the yard and charging facilities are required, then the diesel version with longer operating times and quicker refuelling will be preferred.

However, as oil-based fuel costs continue rising, being able to power machines using electricity produced on site is becoming an increasingly attractive option. Using electrical power is also more environmentally friendly – helping reduce the operation’s carbon footprint and increasing the appeal of the business to customers.

Fendt’s approach is clever – combining highly efficient battery and motor technology with conventional transmission and hydraulic systems to ensure ease of use and compatibility with existing implements.